BARMAC

Barmac® B Series™ impact crushers - Metso

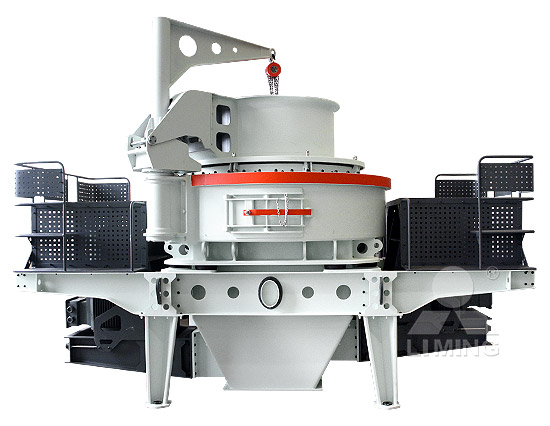

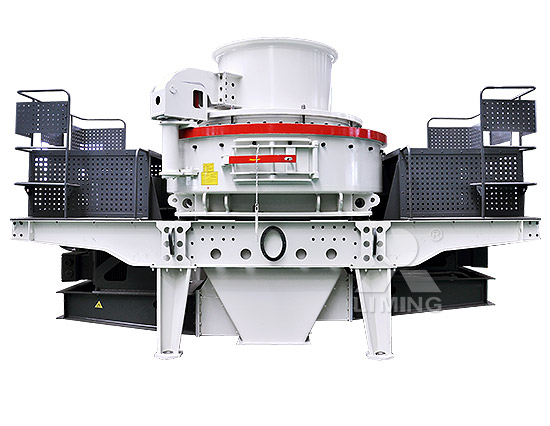

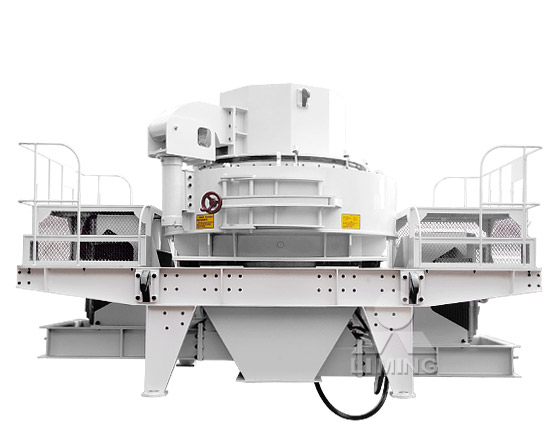

Barmac® crushers are especially useful for producers who are after cubical end products used for example in concrete, asphalt, groundwork materials, manufactured sand, heap leaching, pre-grinding, industrial minerals, and recycling applications.Vertical shaft impact (VSI) crusher. Features. Barmac® B7150SE™ is ideal for the last crushing stage to process rocks, recycled materials, ores, and minerals. It is known for high-quality cubical end products and low operating costs. Contact our sales experts.Barmac® B7150SE™ impact crusher - MetsoBarmac® B9100SE™ VSI crusher is the largest model in Barmac® B Series™ family. it is available as a stationary, portable or mobile crushing unit. Excellent third or fourth stage reduction unit, Barmac® B9100SE™ has proven to be efficient in many demanding crushing operations in construction, industrial minerals, metallic minerals and ...Barmac® B9100SE™ impact crusher - Metso

Barmac® B6150SE™ impact crusher - Metso

Barmac® B6150SE™ is the smallest model in Barmac® B Series™ family. It is excellent crusher for third or fourth stage size reduction. Oftentimes, Barmac® B6150SE™ crusher is used in demanding crushing operations in construction, industrial minerals, metallic minerals and waste recycling applications. High-quality end products.Barmac® VSI-krossar godtar fint material i matningen och låter användaren finjustera stenkrossens prestanda genom att ändra rotorhastigheten eller kaskadmalningsgraden. I Barmac®-krossar går matningsmaterialets primära bana genom rotorn där den kan accelereras upp till 80 m/s innan den släpps ut i krosskammaren.Barmac® B-seriens slagkrossar med vertikal axel (VSI) - Metso2018年10月11日 The main components of the Barmac B-Series VSI are: • Base assembly (including vertical shaft line assembly) • Crushing chamber (including Rotor) • Top assembly (including all feed control options) Barmac B 1100SE series models (2011) The crushers capacity will vary depending on feed material characteristics when work-Barmac B-series VSI Wear parts application guide - Metso

Barmac® B Serie™ Vertikal-Prallbrecher - Metso

Barmac®-Brecher sind besonders nützlich für Hersteller, die kubische Endprodukte anstreben, die z. B. in Beton, Asphalt, Bodenmaterialien, Brechsand, Haufenlaugung, Vormahlung, Industriemineralien und Recyclinganwendungen verwendet werden.2021年12月28日 Availability and serviceability of the Barmac VSI are greatly improved with Orange Series RC Rotors offering both longer wear life and easier servicing. Parts have been designed to more easily interchange and replace components to maximize wear life potential. This is achieved by reconfiguring components when and where needed.Application guide Barmac Orange Series RC Rotor 2018年10月17日 crushing achieved in a Barmac VSI improves the soundness and shape of the material and produces the highest quality end products on the market today. It is widely known that the more cubical your product, the better its performance in concrete, asphalt and base mixtures. Barmac VSI is usually applied in the last phase of theMetso NW Series™ Portable crushing screening plants

Crushers - All crusher types for your reduction needs - Metso

The second type became quite popular in the past decade and is known as the Barmac crusher. The difference between a conventional impactor and a VSI of the Barmac type is that the latter offers lower operating costs, but its reduction ratio is lower also.Barmac® crushers are especially useful for producers who are after cubical end products used for example in concrete, asphalt, groundwork materials, manufactured sand, heap leaching, pre-grinding, industrial minerals, and recycling applications.Barmac® B Series™ impact crushers - MetsoVertical shaft impact (VSI) crusher. Features. Barmac® B7150SE™ is ideal for the last crushing stage to process rocks, recycled materials, ores, and minerals. It is known for high-quality cubical end products and low operating costs. Contact our sales experts.Barmac® B7150SE™ impact crusher - Metso

Barmac® B9100SE™ impact crusher - Metso

Barmac® B9100SE™ VSI crusher is the largest model in Barmac® B Series™ family. it is available as a stationary, portable or mobile crushing unit. Excellent third or fourth stage reduction unit, Barmac® B9100SE™ has proven to be efficient in many demanding crushing operations in construction, industrial minerals, metallic minerals and ...Barmac® B6150SE™ is the smallest model in Barmac® B Series™ family. It is excellent crusher for third or fourth stage size reduction. Oftentimes, Barmac® B6150SE™ crusher is used in demanding crushing operations in construction, industrial minerals, metallic minerals and waste recycling applications. High-quality end products.Barmac® B6150SE™ impact crusher - MetsoBarmac® VSI-krossar godtar fint material i matningen och låter användaren finjustera stenkrossens prestanda genom att ändra rotorhastigheten eller kaskadmalningsgraden. I Barmac®-krossar går matningsmaterialets primära bana genom rotorn där den kan accelereras upp till 80 m/s innan den släpps ut i krosskammaren.Barmac® B-seriens slagkrossar med vertikal axel (VSI) - Metso

Barmac B-series VSI Wear parts application guide - Metso

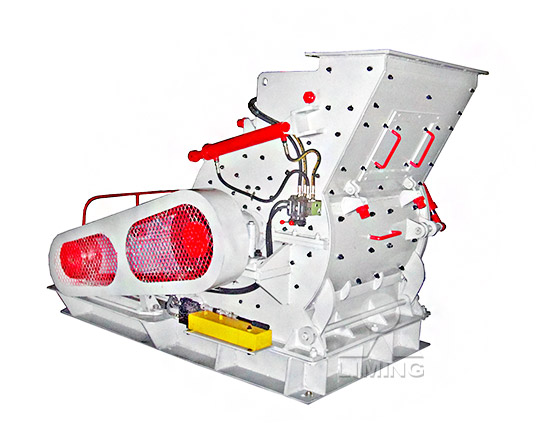

2018年10月11日 The main components of the Barmac B-Series VSI are: • Base assembly (including vertical shaft line assembly) • Crushing chamber (including Rotor) • Top assembly (including all feed control options) Barmac B 1100SE series models (2011) The crushers capacity will vary depending on feed material characteristics when work-Barmac®-Brecher sind besonders nützlich für Hersteller, die kubische Endprodukte anstreben, die z. B. in Beton, Asphalt, Bodenmaterialien, Brechsand, Haufenlaugung, Vormahlung, Industriemineralien und Recyclinganwendungen verwendet werden.Barmac® B Serie™ Vertikal-Prallbrecher - Metso2021年12月28日 Availability and serviceability of the Barmac VSI are greatly improved with Orange Series RC Rotors offering both longer wear life and easier servicing. Parts have been designed to more easily interchange and replace components to maximize wear life potential. This is achieved by reconfiguring components when and where needed.Application guide Barmac Orange Series RC Rotor

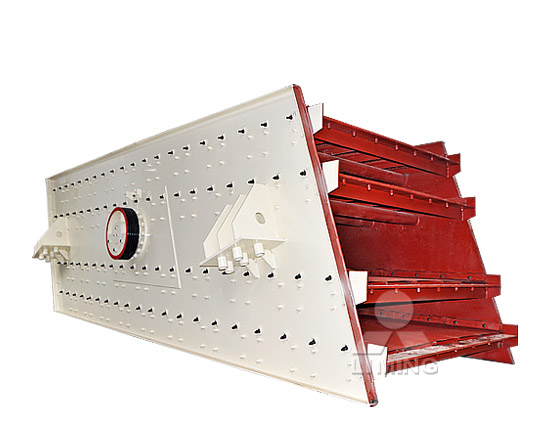

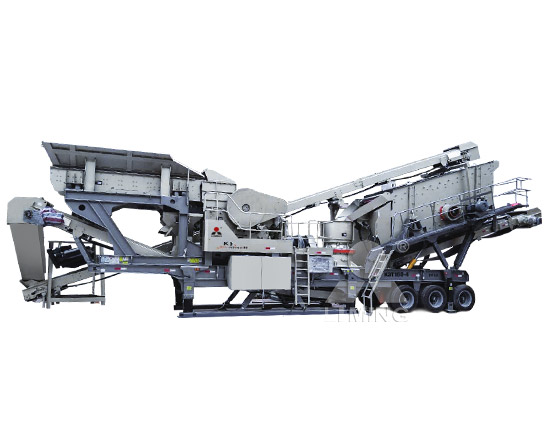

Metso NW Series™ Portable crushing screening plants

2018年10月17日 crushing achieved in a Barmac VSI improves the soundness and shape of the material and produces the highest quality end products on the market today. It is widely known that the more cubical your product, the better its performance in concrete, asphalt and base mixtures. Barmac VSI is usually applied in the last phase of theThe second type became quite popular in the past decade and is known as the Barmac crusher. The difference between a conventional impactor and a VSI of the Barmac type is that the latter offers lower operating costs, but its reduction ratio is lower also.Crushers - All crusher types for your reduction needs - MetsoBarmac® crushers are especially useful for producers who are after cubical end products used for example in concrete, asphalt, groundwork materials, manufactured sand, heap leaching, pre-grinding, industrial minerals, and recycling applications.Barmac® B Series™ impact crushers - Metso

Barmac® B7150SE™ impact crusher - Metso

Vertical shaft impact (VSI) crusher. Features. Barmac® B7150SE™ is ideal for the last crushing stage to process rocks, recycled materials, ores, and minerals. It is known for high-quality cubical end products and low operating costs. Contact our sales experts.Barmac® B9100SE™ VSI crusher is the largest model in Barmac® B Series™ family. it is available as a stationary, portable or mobile crushing unit. Excellent third or fourth stage reduction unit, Barmac® B9100SE™ has proven to be efficient in many demanding crushing operations in construction, industrial minerals, metallic minerals and ...Barmac® B9100SE™ impact crusher - MetsoBarmac® B6150SE™ is the smallest model in Barmac® B Series™ family. It is excellent crusher for third or fourth stage size reduction. Oftentimes, Barmac® B6150SE™ crusher is used in demanding crushing operations in construction, industrial minerals, metallic minerals and waste recycling applications. High-quality end products.Barmac® B6150SE™ impact crusher - Metso

Barmac® B-seriens slagkrossar med vertikal axel (VSI) - Metso

Barmac® VSI-krossar godtar fint material i matningen och låter användaren finjustera stenkrossens prestanda genom att ändra rotorhastigheten eller kaskadmalningsgraden. I Barmac®-krossar går matningsmaterialets primära bana genom rotorn där den kan accelereras upp till 80 m/s innan den släpps ut i krosskammaren.2018年10月11日 The main components of the Barmac B-Series VSI are: • Base assembly (including vertical shaft line assembly) • Crushing chamber (including Rotor) • Top assembly (including all feed control options) Barmac B 1100SE series models (2011) The crushers capacity will vary depending on feed material characteristics when work-Barmac B-series VSI Wear parts application guide - MetsoBarmac®-Brecher sind besonders nützlich für Hersteller, die kubische Endprodukte anstreben, die z. B. in Beton, Asphalt, Bodenmaterialien, Brechsand, Haufenlaugung, Vormahlung, Industriemineralien und Recyclinganwendungen verwendet werden.Barmac® B Serie™ Vertikal-Prallbrecher - Metso

Application guide Barmac Orange Series RC Rotor

2021年12月28日 Availability and serviceability of the Barmac VSI are greatly improved with Orange Series RC Rotors offering both longer wear life and easier servicing. Parts have been designed to more easily interchange and replace components to maximize wear life potential. This is achieved by reconfiguring components when and where needed.2018年10月17日 crushing achieved in a Barmac VSI improves the soundness and shape of the material and produces the highest quality end products on the market today. It is widely known that the more cubical your product, the better its performance in concrete, asphalt and base mixtures. Barmac VSI is usually applied in the last phase of theMetso NW Series™ Portable crushing screening plantsThe second type became quite popular in the past decade and is known as the Barmac crusher. The difference between a conventional impactor and a VSI of the Barmac type is that the latter offers lower operating costs, but its reduction ratio is lower also.Crushers - All crusher types for your reduction needs - Metso